ME3492 Hydraulics and Pneumatics Important Questions

Unit 1

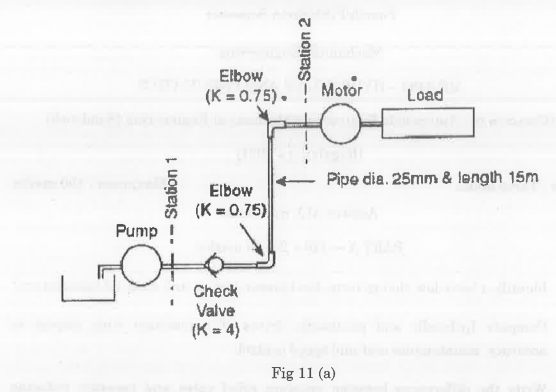

- The system shown in Figure 11 (a) contains a hydraulic pump delivering high pressure oil of specific gravity 0.9 and kinematic viscosity 1.25 * 10 ^ – 4 * m ^ 2 / s to a hydraulic motor. A 25 m pipe of internal diameter 30 mm and thickness of 10 mm connects the pump and motor. The pipe has two elbow fittings (k = 0.7) and one check valve (k = 4) The motor is placed 10 m above the pump. The pressure required to drive the loaded motor is 40 bar. Determine the pump discharge pressure, if the discharge from the pump is 180 lpm

- Explain any six desirable properties of hydraulic oil used for industrial automation.

- Mention the criteria for selection of such fluids for hydraulic applications.

- What are some potential implications of Pascal’s Law for the design and operation of hydraulic systems, and how might these implications influence the decision-making process of engineers and technicians in this field? Explain.

- With a neat sketch, explain the working principle, construction, application, and limitation of an unbalanced vane pump.

- A hydraulic cylinder is to compress a body down to bale size in 10s. The operation requires a 3 m stroke and a 40000 N force. If a 10 MPa pump has been selected, assuming the cylinder to be 100% efficient, find

(i) The required piston area

(ii) The necessary pump flow rate

(iii) The hydraulic power delivered to the cylinder

(iv) The output power delivered to the load

(v) Also, solve parts (i) to (iv) assuming a 400 N friction force and a leakage of 1 LPM. What is the efficiency of the cylinder with the given friction force and leakage? - A pump has a displacement volume of 120 cm³. It delivers 0.0015 m³/s at 1440 RPM and 60 bar. If the prime mover input torque is 130 Nm.

(i) What is the overall efficiency of the pump?

(ii) What is the theoretical torque required to operate the pump?(iii) The pump is driven by an electric motor having an overall efficiency of 88%. The hydraulic system operates 12 hours/day for 250 days per year. The cost of electricity is Rs 8 per kWh. Determine the yearly cost of electricity to operate the hydraulic system.

Unit 2

- Explain the working principle of 4/2 solenoid operated direction control valve for hydraulic applications.

- With neat circuits, explain the application of any four pressure control valves.

- Classify the flow control valve with examples and how it is different from direction control valves.

- What are some Key factors to consider when selecting a hydraulic actuator for a specific application, and how might these factors influence the performance and efficiency of the overall hydraulic system? Explain.

- A vertical punching machine requires a hydraulic valve to prevent the piston from free falling due to gravity’ with a neat sketch, design a hydraulic circuit appropriate for this application. Also, explain the construction and working principle of the hydraulic valve.

- A hydraulic motor receives a flow rate of 72 LPM at a pressure of 12000 kPa. If the motor speed is 800 RPM and if the motor has power loss of 3 kW, find the motor’s actual output torque and overall efficiency.

- Define the displacement and torque ratings of a hydraulic motor.

- Why the torque output from a fixed-displacement hydraulic motor operating at constant pressure is the same regardless of speed changes?

Unit 3

- With neat circuits explain the four applications of an accumulator in hydraulic circuits.

- What is the condition for the speeds of extension and retraction strokes to be equal? Design hydraulic circuit accordingly.

- A hydraulic cylinder is to compress a car body in 20 seconds. The operation requires a stroke of 6 m and a force of 60,000N. If a 10 N/mm² pump has been selected, then calculate the pump flow and hydraulic power capacity in kW.

- What are some potential advantages and disadvantages of using open-loop versus closed-loop hydraulic systems? How may these variables, affect the decision to choose a given system for a particular application? Explain.

- Design the circuits for the following applications:

(i) Synchronous actuation of two similar hydraulic actuators

(ii) Fail-Safe Operation

(iii) Regenerative - With a block diagram explain the working of electro-hydraulic servo valves. (6)

- What are proportional valves? Explain how to control the force and spool position in proportional hydraulic valves.

Unit 4

- How do electro-pneumatic systems differ from purely pneumatic systems, and what are some advantages and disadvantages of using electro-pneumatic systems? Explain.

- What is the cascade method of designing fluid power circuits, and how does it differ from other methods of circuit design? Explain.

- Design a pneumatic sequencing circuit for the sequence A+ A- B+ B-C+ C-using cascade method.

- Elaborate on the working of regulator and lubricator in a pneumatic FRL unit.

- Construct a pneumatic sequential circuit for the sequence A+B+B-C-C+A using the cascade method and incorporate a cycle selection module.

- Badges are to be produced from a very thin metal sheet. A press with a stamping die is available for this purpose. The double-acting cylinder should extend when both the push buttons S1 and S2 are pressed simultaneously. The return stroke is to occur automatically only after the forward end position and preset pressure have been reached to get consistent quality. The cylinder should immediately retract if the emergency push button S3 is pressed. Draw an electro-pneumatic ladder diagram for the above application.

Unit 5

- Discuss the criteria for the selection of cylinders.

- Briefly explain the important factors in the maintenance of hydraulic and pneumatic systems.

- Draw the schematic layout of a typical hydraulic power pack and explain the function of its elements.

- Discuss compressors and their classifications in detail. Also, discuss the various stages of air treatment.

- How can a systematic troubleshooting approach be applied to identify and resolve common problems that arise in hydraulic and pneumatic systems, and what are some examples of real-world applications where this approach has been successfully implemented? Explain.

- What are some basic factors that should be considered when selecting a low cost automation technique for a specific industrial application, and why are these factors important? Explain.

- Sketch and explain the elements in a hydraulics power pack.

- An industry is interested in developing a hydraulic drilling machine to drill 10 mm thick steel plates. Since, the cycle time of the process has to be minimum, faster approach and retraction strokes are essential. A powerpack with a single pump system is already available with the industry and hence the same is proposed to be used. As an automation engineer, develop an appropriate circuit to achieve the above objectives. Justify that the extension velocity is faster than in the conventional hydraulic circuit and derive the expression for velocity ratio.